When towing a 15-ton trailer, having the right braking system is essential for safety, control, and reliability. The size and weight of such a large trailer require powerful brakes that can manage the significant demands of heavy towing. This is where 15-ton trailer electric brakes come into play. Designed to handle the increased load, these electric brakes provide the necessary stopping power for trailers used in industries such as construction, farming, and transport. In this guide, we will explore how 15-ton trailer electric brakes work, their benefits, installation tips, and maintenance advice to ensure optimal performance.

What Are 15 Ton Trailer Electric Brakes?

15-ton trailer electric brakes refer to a braking system specifically engineered for trailers with a gross vehicle weight of up to 15 tons. These systems use electrical signals from the tow vehicle to activate the brakes on the trailer, allowing for proportional and smooth stopping power that can be adjusted based on the load. Due to the significant weight involved, these electric brakes are designed with heavy-duty components to ensure they can handle the intense demands of towing such large trailers.

How Do 15 Ton Trailer Electric Brakes Work?

Electric trailer brakes operate using an electrical signal from a brake controller installed in the towing vehicle. Here’s a step-by-step explanation of how they work:

- Brake Controller Activation: When the driver applies the brakes in the towing vehicle, the brake controller sends an electrical signal to the trailer’s braking system.

- Magnet Engagement: This signal activates the magnets inside the brake assemblies, which then engage with the brake drums or discs.

- Brake Shoe or Pad Engagement: The magnets cause the brake shoes or pads to press against the inner surface of the brake drum or disc, creating friction that slows the wheels.

- Proportional Braking: The brake controller adjusts the intensity of the braking force based on how much pressure is applied to the towing vehicle’s brakes, ensuring smooth and controlled stops even under heavy loads.

Benefits of 15 Ton Trailer Electric Brakes

There are several significant benefits to using electric brakes on a 15-ton trailer, making them an excellent choice for heavy-duty towing:

- Superior Stopping Power: These brakes are designed to handle the immense stopping force needed to slow down or stop a trailer that weighs 15 tons, making them essential for safety.

- Proportional Braking: Electric brakes offer smooth, controlled braking by adjusting the force applied based on the braking pressure from the tow vehicle, reducing the risk of jackknifing or trailer sway.

- Durability: Heavy-duty components are used in these brakes to withstand the wear and tear of towing massive loads, ensuring long-lasting performance and reliability.

- Cost-Effective Maintenance: Compared to hydraulic brake systems, electric trailer brakes are generally easier to maintain and more affordable, making them a practical choice for operators of heavy trailers.

How to Install 15 Ton Trailer Electric Brakes

Installing 15-ton trailer electric brakes requires mechanical knowledge and the proper tools. Here’s a step-by-step guide to help you through the process:

1. Prepare the Trailer

Park the trailer on a flat, stable surface and secure it with wheel chocks. Use a jack to lift the trailer axle off the ground so that the wheels are free to be removed.

2. Remove Existing Brake Components

If your trailer already has a braking system, you’ll need to remove the existing brake drums, shoes, or pads to install the new electric brakes. Clean the axle flange and surrounding areas to ensure proper installation of the new components.

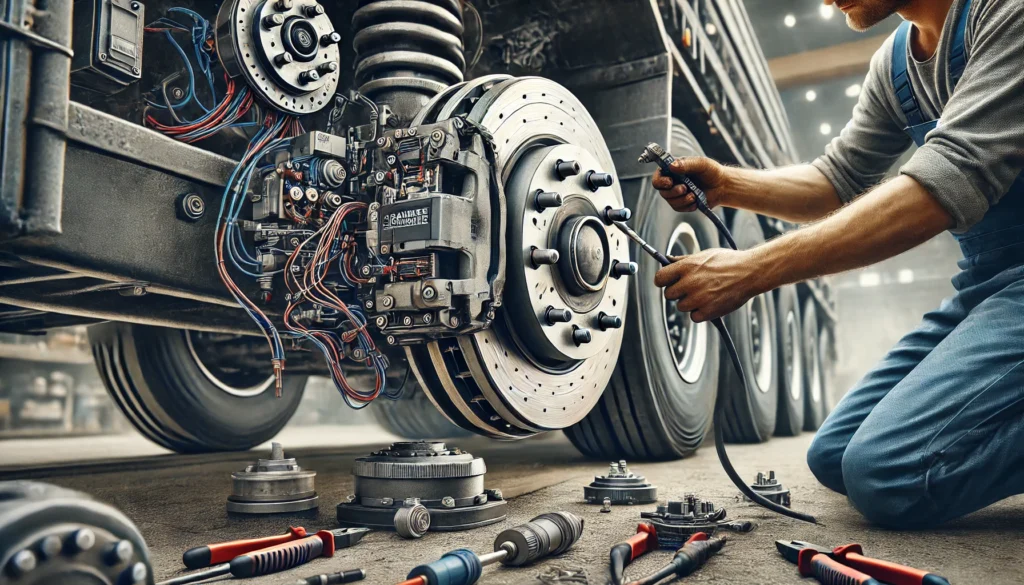

3. Install the Electric Brake Assemblies

Mount the new 15-ton electric brake assemblies onto the axle flange, ensuring they are correctly aligned. Secure the assemblies with bolts and follow the manufacturer’s specifications for tightening.

4. Connect the Wiring

Run the wiring from the brake controller in the towing vehicle to the trailer’s brake assemblies. Ensure that all connections are secure, waterproofed, and free from corrosion to avoid electrical issues down the road.

5. Install the Brake Drums or Discs

Slide the brake drums or discs over the assemblies, ensuring they fit snugly and rotate smoothly when the brakes are not engaged. Reinstall the wheels securely.

6. Test the Braking System

Once everything is installed, perform a thorough test of the braking system. Use the brake controller to apply the trailer brakes and verify that they engage smoothly and effectively. Make any necessary adjustments to the brake controller to ensure optimal performance.

Maintenance Tips for 15 Ton Trailer Electric Brakes

To ensure safe towing and long-lasting performance, proper maintenance of your 15-ton trailer electric brakes is essential. Here are some tips to help keep your brakes in top condition:

- Regular Inspections: Check the brake shoes or pads, drums or discs, and magnets for wear and damage. Replace any worn components to maintain effective braking.

- Clean the Brake Components: Dirt, debris, and rust can accumulate on the brake components, reducing their efficiency. Regularly clean the brake assemblies to prevent buildup and ensure optimal performance.

- Check Wiring Connections: Ensure that all electrical connections are secure and free from corrosion. Damaged or loose wiring can lead to brake failure or reduced performance.

- Adjust Brake Controller Settings: Depending on the load and road conditions, you may need to adjust the brake controller settings to provide the right amount of braking force for the trailer.

Conclusion

For those towing 15-ton trailers, electric brakes are an indispensable part of ensuring safety and control. With their ability to provide proportional and powerful braking, these systems are essential for trailers carrying heavy loads. By understanding how they work, following proper installation procedures, and maintaining your electric brakes regularly, you can tow with confidence knowing that your braking system is up to the task.