The electric trailer brake system is a critical component in ensuring the safety and control of your trailer during towing. Whether you’re hauling a small camper or a heavy-duty trailer, understanding how this system works and how to maintain it is essential for safe travel.

What is an Electric Trailer Brake System?

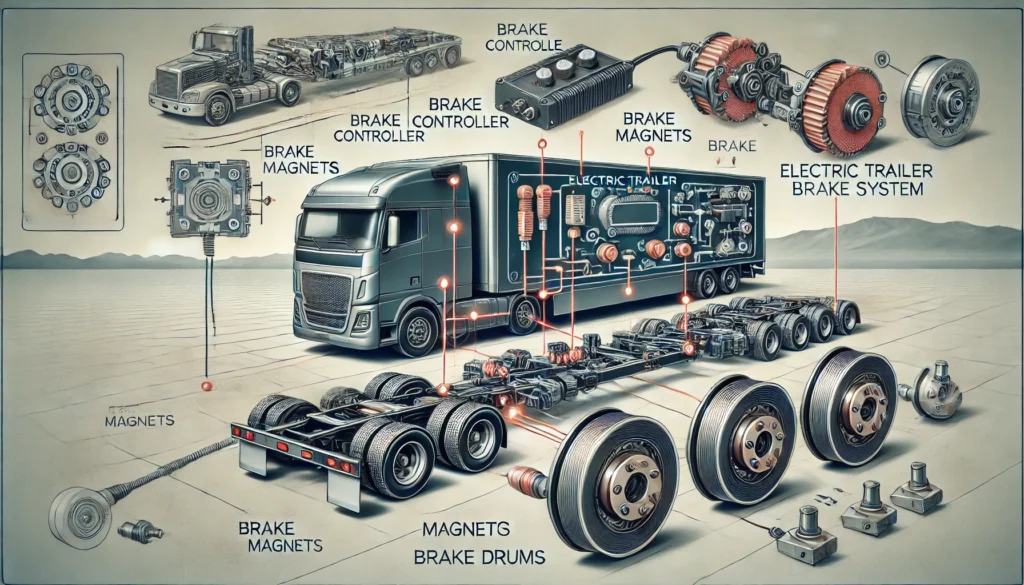

An electric trailer brake system is designed to provide controlled braking power to your trailer. Unlike hydraulic systems that rely on fluid pressure, electric brakes use electrical signals from a brake controller in your tow vehicle to engage the trailer’s brakes. This system offers precise control, allowing you to adjust the braking force based on the load and road conditions.

How Does the Electric Trailer Brake System Work?

The system operates through a brake controller mounted inside your tow vehicle, usually under the dashboard. When you apply the brakes in your vehicle, the controller sends an electrical signal to the trailer brakes. This signal activates an electromagnet inside the brake drum, which pushes the brake shoes against the drum, creating friction and slowing the trailer.

The intensity of the braking can be adjusted through the brake controller, allowing you to increase or decrease the braking force depending on the weight of the trailer and the terrain you’re traveling on.

Key Components of an Electric Trailer Brake System

To fully understand your electric trailer brake system, it’s important to know its main components:

- Brake Controller: This device sends the electrical signal to the trailer brakes.

- Brake Magnets: These electromagnets are activated by the signal from the controller, causing the brake shoes to engage.

- Brake Drums: The brake shoes press against these drums to create the friction needed to slow down the trailer.

- Wiring: Electrical wiring connects the brake controller to the trailer brakes.

Common Issues with Electric Trailer Brake Systems

Despite their reliability, electric trailer brake systems can encounter problems. Here are some common issues:

- Weak or Inconsistent Braking: This may be caused by poor connections, worn brake shoes, or a faulty brake controller.

- Brakes Not Engaging: If the brakes fail to engage, it could be due to a broken wire, a malfunctioning brake controller, or a faulty ground connection.

- Overheating Brakes: Overheating can occur if the brakes are constantly engaged due to a misadjusted controller or malfunctioning components.

Maintenance Tips for Electric Trailer Brake Systems

To keep your electric trailer brake system in top condition, regular maintenance is essential:

- Inspect the Wiring: Regularly check all electrical connections for signs of wear, corrosion, or damage.

- Test the Brake Controller: Periodically test the brake controller to ensure it’s sending the correct signals to the trailer brakes.

- Check the Brake Shoes: Inspect the brake shoes for wear and replace them as needed.

- Clean the Brake Drums: Remove any dirt or debris from the brake drums to ensure smooth operation.

Why Regular Maintenance is Important

Regular maintenance not only ensures the safety of your trailer but also extends the life of the brake system. By catching small issues before they become major problems, you can avoid costly repairs and keep your trailer in safe, working condition.

Conclusion

The electric trailer brake system is a vital part of any towing setup, providing the control and safety needed for hauling loads of any size. Understanding how the system works and performing regular maintenance will ensure that your trailer is always ready for the road.