When it comes to towing a trailer, ensuring that your braking system is reliable and efficient is crucial for safety. One of the most common setups for trailers is the combination of electric trailer brakes and drums. This system has been a staple in the towing industry for years, offering a balance of performance and affordability. In this post, we’ll dive into the mechanics of electric trailer brakes and drums, how they work together, and why they might be the right choice for your trailer.

What Are Electric Trailer Brakes?

Electric trailer brakes are a type of braking system that uses electrical power from the towing vehicle to activate the trailer’s brakes. These brakes are controlled by a brake controller, which is typically installed inside the towing vehicle. The controller sends a signal to the trailer brakes, engaging them in proportion to the vehicle’s braking force.

Electric brakes are commonly used because they provide a smooth and adjustable braking force, making them ideal for varying loads and conditions.

The Role of Brake Drums in the System

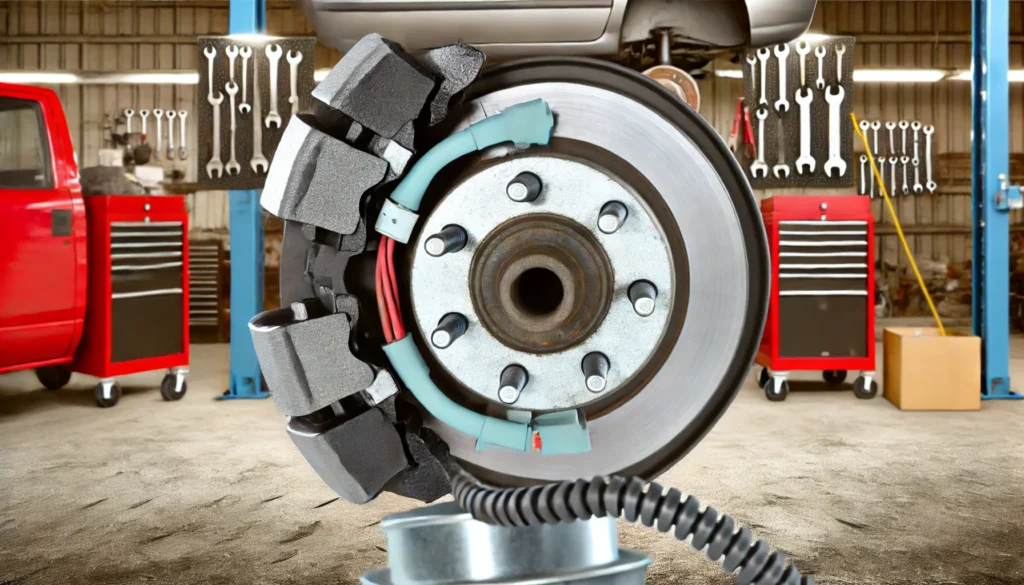

The brake drum is a cylindrical component that plays a key role in the braking process. When the electric brakes are activated, brake shoes inside the drum expand outward to press against the inner surface of the drum. This contact creates friction, which slows down the trailer.

Brake drums are known for their durability and ability to handle high levels of heat, making them a reliable choice for trailers that frequently carry heavy loads. However, they do require regular maintenance to ensure they continue to function correctly.

How Electric Trailer Brakes and Drums Work Together

The interaction between the electric brakes and the drums is crucial for effective braking. When the brake controller in the towing vehicle sends a signal, the electromagnets inside the brake assembly are energized. This magnetism causes the brake shoes to move outward and press against the brake drum. The friction generated by this contact slows the rotation of the trailer’s wheels, thereby bringing the trailer to a stop.

This system allows for precise control over the braking force, which can be adjusted based on the weight of the load being towed. It’s this adjustability that makes electric brakes and drums a popular choice for many trailer owners.

Maintenance Tips for Electric Trailer Brakes and Drums

Maintaining your electric trailer brakes and drums is essential for ensuring their longevity and performance. Here are a few key maintenance tips:

- Regular Inspections: Check the brake shoes and drums for wear and tear. If you notice grooves or cracks in the drums, or if the brake shoes are worn thin, it’s time to replace them.

- Cleaning and Lubrication: Keep the brake assembly clean and free from dirt and debris. Lubricate moving parts as needed to prevent corrosion and ensure smooth operation.

- Adjusting the Brakes: Over time, the brake shoes may need adjustment to maintain proper contact with the drums. This can typically be done manually or through a self-adjusting mechanism, depending on your system.

- Check the Wiring: Ensure that the wiring from the brake controller to the trailer is intact and free from damage. Poor wiring can lead to inconsistent braking performance.

Why Choose Electric Trailer Brakes and Drums?

Electric trailer brakes paired with drums offer a reliable, cost-effective solution for trailer braking. They are particularly well-suited for trailers that carry heavy loads, as the drum design handles heat and stress efficiently. Additionally, the ease of control provided by the brake controller allows for smooth and safe braking, regardless of the driving conditions.

Conclusion

Understanding the role and function of electric trailer brakes and drums is essential for any trailer owner. This system provides the necessary braking power to ensure safe towing, especially when dealing with heavy loads. Regular maintenance and proper use will keep your trailer’s brakes performing at their best, ensuring peace of mind on the road.